Laser-Based Spot Size Eutectic Bonding

Our lasers guarantee the fastest eutectic bonds

Heat Plate-Based Eutectic Bonding

Highest reliability and yield

Epoxy Bonding

Passive assembly of VCSELs, lenses or injection moulded parts

Fibre Coupling

Aifotec assembles fibres or optical cables with active coupling to your chip

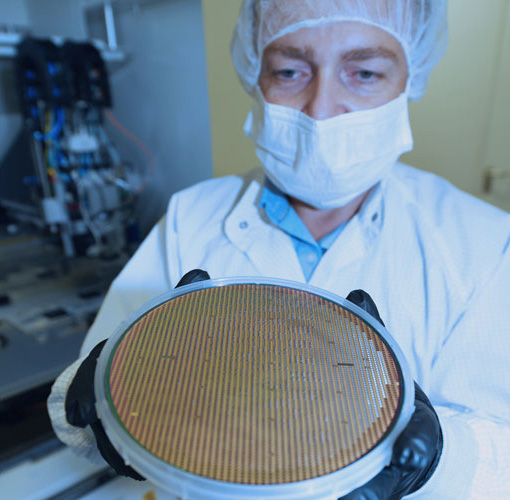

Aifotec is a recognised specialist in integrated circuit packaging for photonic and semi-conductor components. Our speciality is high-precision, fully automatic assembly.

Aifotec supports all leading process equipment such as glass, ceramic, polymer and silicon with laser spot size die bonding. We also support advanced oven-based epoxy bonding technologies.

Laser-Based Spot Size Eutectic Bonding

Aifotec’s laser-based spot size bonding provides precise passive assembly of up to ± 0.5 μm @ 3 sigma. The advantage of our technology is as follows: The local heat penetration through the laser system guarantees a very fast eutectic bonding process with little oxide formation and low heat impact on neighbouring fields

Heat Plate-Based Eutectic Bonding

The eutectic bond through our heat plate system offers our customers the option to assemble even very large components with an accuracy of ± 1.5 μm.

Epoxy Bonding

Epoxy technology using a light-curing or conductive epoxy, as well as passive or active adjustment allow for multiple component assembly options.

Fibre Coupling

Aifotec realises the active optical coupling of individual fibres or fibre arrays to your chip.

The active coupling is realised with the optical cables using a technology patented by Aifotec with the smallest external dimensions.